| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Place of Origin : JIANGSU, CHINA

Brand Name : TONGDA

Packaging Details : PE film, PE bag, Wooden Cases, Wooden Pallet, etc.

Supply Ability : 800sets/year

Price : $35,000.00 - $85,000.00/Sets

Certification : CE, ISO9001

MOQ : 1SET

Delivery Time : 28 working days

Payment Terms : T/T, L/C, D/P, West Union

Model Number : TONGDA HSII-5L

Core Components : PLC, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

Plastic Processed : PP, HDPE, PC, ABS, PVC, PE, EVA, PA, ABS/PP, PE/PP, HDPE/PP, PETG

Voltage : Customized to customer needs

Dimension(L*W*H) : 4.9m*3.1m*3.2m

Hollow part volume : 1-5L

Clamping Force (kN) : 110

PLC Brand : MITSUBISHI

Screw L/D Ratio : 25

Screw diameter (mm) : 80 mm

Output (kg/h) : 110 kg/h

Automation : Automatic

No. of Screw Heating Zone : 5

Screw Heating Power(kW) : 19 kW

Extruder Motor Power(kW) : 30 kW

Mold Platen Size(Width)(mm) : 480 mm

Mold Platen Size(Height)(mm) : 450 mm

Air Pressure(MPa) : 0.6 MPa

Air Comsumption(m³/min) : 0.8 m³/min

Die Head Heating Power(kW) : 10.7 kW

Power (kW) : 80

Weight (T) : 9

Key Selling Points : Long Service Life

Applicable Industries : Energy & Mining, Hotels, Home Use, Machinery Repair Shops, Restaurant, Food & Beverage Factory, Farms

Showroom Location : Egypt, Indonesia, Pakistan, Thailand, Chile, Algeria

Rotary Cylinder Brand : FESTO

Station : Double Station

Suitable bottle : 1-5L

Key words : Automatic Extrusion Blow Moulding Machine

Packing : Wooden

Use : Hollow Moulding

Parison Control : MOOG

Max. Size of Mold : 480*450

Color : Blue

TONGDA HSII-5L 200ML 2L 5L plastic bottle making machine blowing machine blow molding machines

This is our best series machine.This is hydraulic servo system.The clamping unit is elbow style and the clamping force is more uniform.It is high speed and energy-saving. This machine is suitable for ry pack wipes disinfecting wet wipes canister/Daily chemical vegetable wash fruit cleaning /cream lotion cosmetic bottle, etc.It can be also equipped with several die-heads and then to make the small product.

| MODEL | Units | HSII-5L | Remarks: we will customize the most suitable machinery according to your requirements |

| Max. Product volume | L | 5 | |

| Output of HDPE | kg/h | 110 | |

| Clamping force | kn | 110 | |

| Screw diametre | mm | 80 | |

| Screw heating power | kw | 19 | |

| Blow pressure | mpa | 0.6 | |

| Size of machine | m | 4.5*2.7*3.1 |

Product Details

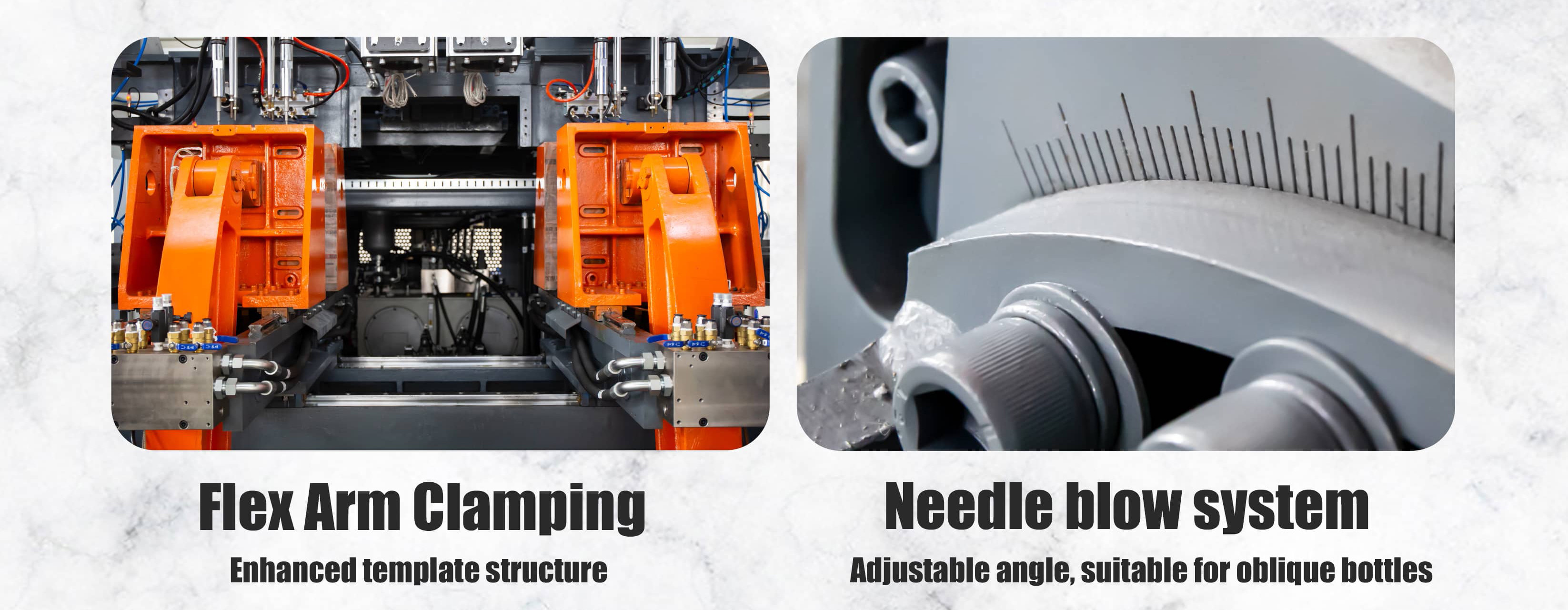

Flex Arm Clamping:Enhanced template structure

Needle blow system:Adjustable angle, suiable for oblique bottles

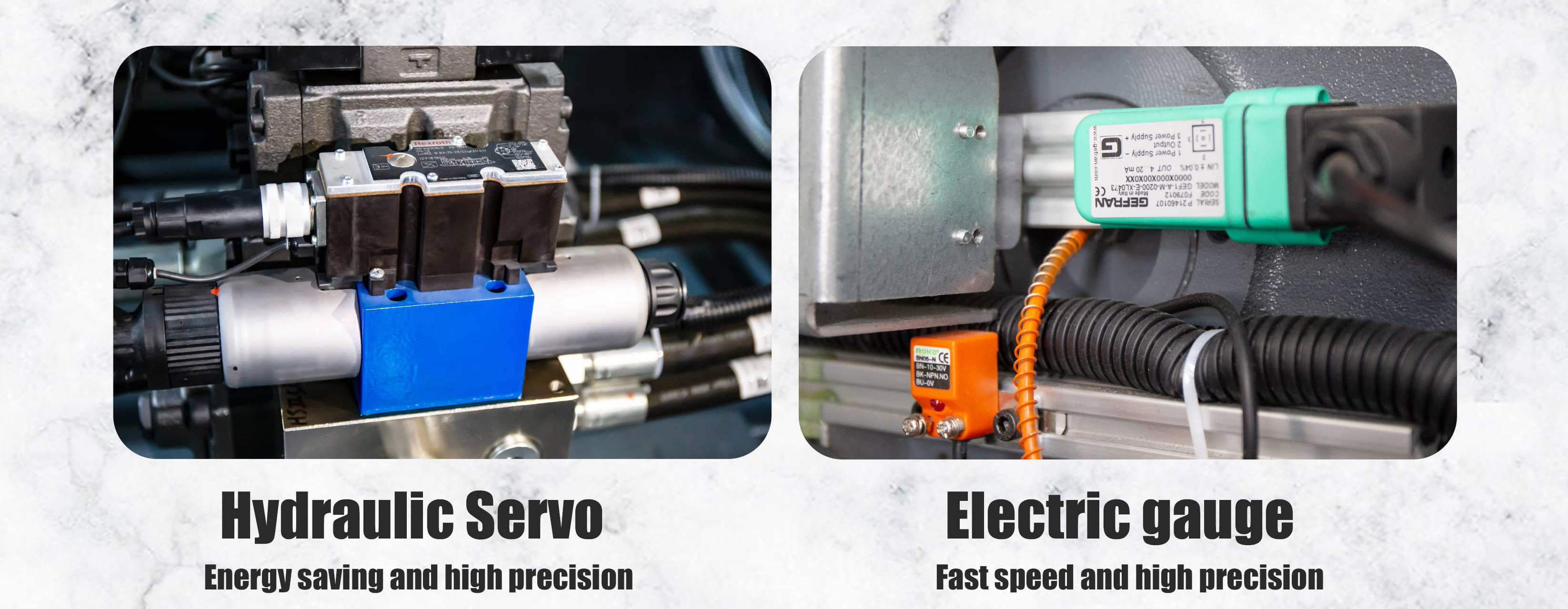

Hydraulic Servo:Energy saving and high precision

Electric gauge:Fast speed and high precision

Company Information

Suzhou Tongda Machinery have more than 20,000m2 factory buildings and other facilicities and a new intelligent manufacturing factory with 55,000m2 area. The I phase 20,000m2 area factory will be put into use in June, 2022. And on May 19th, 2022, we just held the II phase intelligent manufacturing base groundbreaking ceremony.

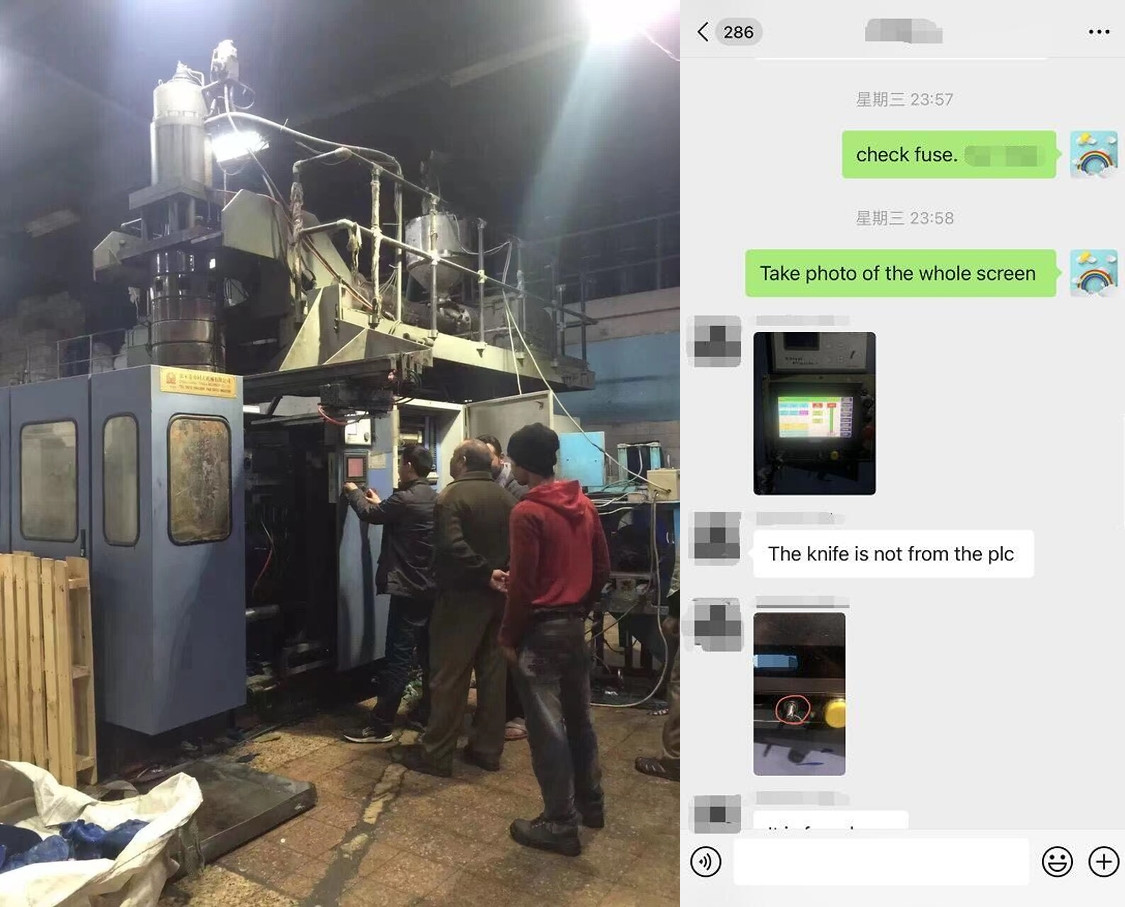

After-sales services

Tongda has a sound service network, perfect after-sales service system, 14 professional after-sales service teams across the country, and a timely response service mechanism to continuously improve user satisfaction. Serve every customer sincerely, respond quickly, and solve the problems raised by customers in a timely manner. We will regularly send debugging engineers to visit customers and solve problems in time.

FAQ

TONGDA sales consultant

1. We can provide comprehensive and professional Suggestions on equipment selection.

2. Energy consumption calculation and investment income analysis can be provided.

3. Provide tailor-made CAD drawings of workshop layout and product optimization Suggestions.

4. Extrusion plastic bottle blow molding machine has remote maintenance function

Advantages of TONGDA tech teams

1. 800 sets of customized requirements per year enable us to have rich experience across multiple industries.

2. Customize equipment models according to customer product characteristics.

3. Project responsibility system, closed-loop team cooperation between the design team and the process team, adjustment of the team, and joint creation of equipment that users are satisfied with.

4. Engineers can study abroad or participate in technical function training of the industry to master the latest information and technical trends of the industry.

5. Undertake a number of large projects, and has a group of senior technical personnel composed of the construction team, can build cable bridge, installation of a complete set of equipment.

Advantages of TONGDA after-sales team

1. Lifetime free service for the machine.

2. Quick response all day long.

3. Set up domestic service team and international service team.

4. Technicians also master the debugging and maintenance of auxiliary equipment.

5. A free 2-day training course will be provided to customers every year.

6. Special processing equipment to produce after-sales accessories to ensure rapid response to user needs.

|

|

200ML 2L 5L Daily Chemical Bottle Blow Molding Machine Double Station Images |